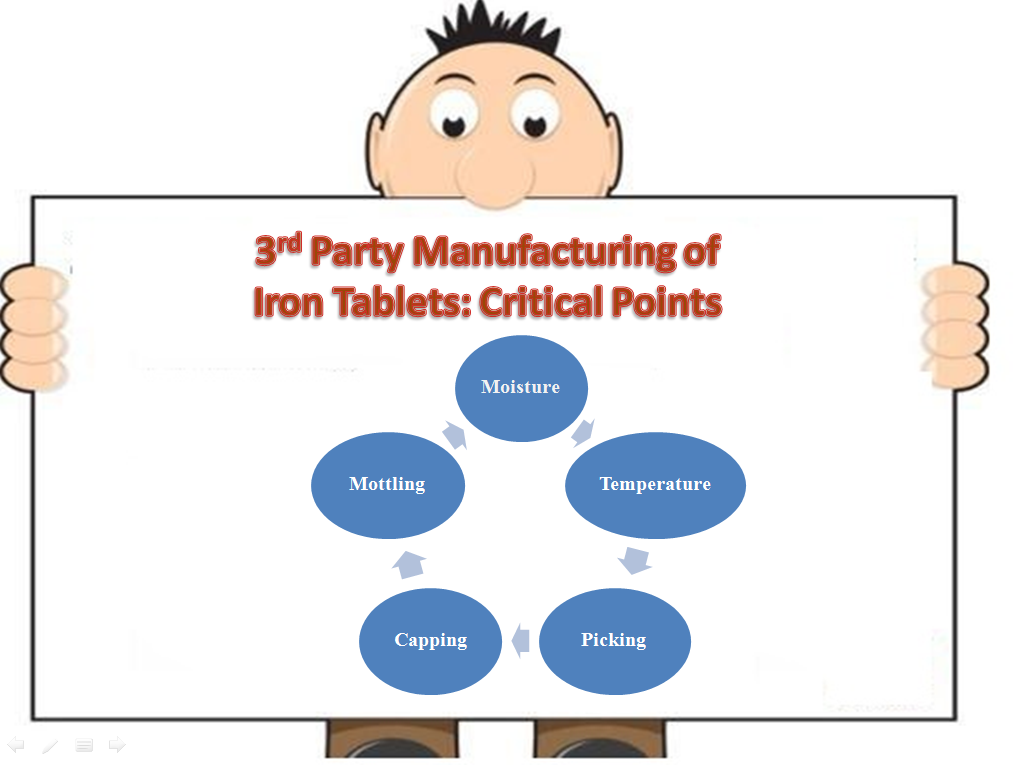

Third Party Manufacturing of Iron Tablets: Critical Points

Iron is a crucial supplement and has huge consumption. The iron formulation is sensitive to light and moisture and improper manufacturing or storage conditions deteriorate it very fast. Third party manufacturing of Iron pills/Tablets/capsules is very critical and must be done very very carefully.

As we talk about the third party manufacturing of iron pills, sometimes while having the iron pill it may wonder you how these pills are manufactured. What mechanism, what procedure, what ingredients and how much quantity and which instruments would behind the manufacturing of such a beautiful embossed tablet. Nowadays, there are different kinds of tablets available in the market, different colour, shape and printing on it. As the iron tablets seem to be beautiful and polished but there are certain problems come during the manufacturing of the particular iron tablet.

Moisture: Moisture content in the environment or we can say that the humidity plays a major role in the tablet manufacturing. For iron pills, the manufacturing scenario and the storage have an optimized level of humidity. The iron pills are very sensitive to humidity. It can influence the physicochemical properties of iron pills like hardness, disintegration time and dissolution rate. These changes may alter bioavailability, and therapeutic efficacy, even though the drug potency.

Temperature: Together with humidity, temperature also influences the manufacturing process of the iron pills. An experiment was conducted by the scientists to determine the influence of temperature and moisture content on the potency of the iron tablet which gives evidence of the effect of temperature and moister on the iron tablet, which converts ferrous to ferric form in the tablet that is not soluble and not absorbed by the gastrointestinal tract. This causes the loss in desired treatment or less effect to desired treatment.

Picking: Just like the normal tablet, the iron tablet also encounters picking problem during the manufacturing problem. Inaccurate addition of the excipients is the major cause of picking. During the manufacturing process, the upper portion of the tablet gets sticks to the punch surface and gets eroded from the tablet surface. Various factors are responsible for it like rough punch surface, the Sticky surface of the tablet; hot granules while compression and excess moisture. This problem is minimized by the proper drying of granules, reduce the amount of or change the binder so that the adhesive force is decreased more cohesive it becomes.

Capping: There is a complete or partial separation of upper and lower surface of the tablet horizontally. This hurdle arises due to entrapment of air in the tablet material and tablets get separated out in two layers. Large no. of fines in the material, too much-dried granules, inadequate binder and improper compression are the major reasons for this problem. By the addition of the proper amount of binder, by removing fines from granules and by proper compression it can be minimized.

Mottling: coloured pills seem to be very nicely polished. But, many problems occur during the colouration of the tablets. Mottling is one of the problems arises during colouration. It is the uneven distribution of the colour on the surface of the tablet, with dark and light patches on it. Degradation of the excipients with the different colour is the major reason mottling. Improper mixing of the coloured excipients is another reason for the mottling. The proper addition of coloured binder and proper mixing of excipients leads to the removal of mottling.

Tablet is the novel dosage form having the greatest dose precision and least content and has the lowest cost of all oral dosage form. The iron in the tablet form is most suitable. We can add other nutrients with the iron in one dosage form. For Third Party Manufacturing of Iron tablets it crucial to look for quality systems and technical know-how as it can have the long-term impact on patient health and companies reputation.

Leave a Comment

(0 Comments)